In order to achieve a safe supply of high quality tea,

We have established “quality control”, “stock capacity” and “distribution system.”

FSSC22000

Organic JAS

HALAL certification

Kosher certification

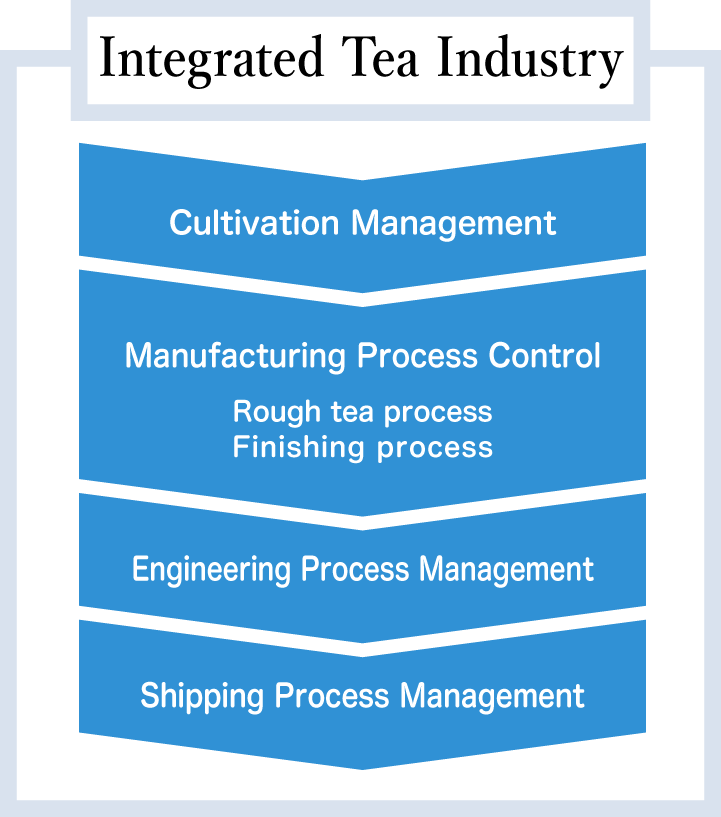

Making tea at Yamama

General management of Yamama Masudaen

Please watch this video. It introduces the integrated tea industry we are working on in an easy-to-understand manner.

Cultivation management

We have built a “traceability system” and cooperate with farmers to ensure safe tea production by thoroughly maintaining the “pesticide safety use pledge”, “tea garden cultivation management record book” and “tea garden ledger”. Together with cooperating farmers, we patrol the tea plantation and grasp the growth situation of the year, predict the start time of picking, yield, and pest control.

Manufacturing process control

We manage the rough tea process and the finishing tea process. In the process, we are trying to thoroughly utilize the flowchart and check function. By visualizing such management work, we believe that “safety and security” can be delivered to our customers.

Production

Scales

| Head office and finishing factory | 2,600㎡ |

| Rough tea factory | 844㎡ |

| Warehouse | 660㎡ |

Ability

| Finished line | 2,500kg /day |

| Bag packaging line | 5,000bags/day |

| Tea bag line | 15,000pieces/10g/day |

| Rough tea production line | 13,000kg /day |

| Grinding factory line | 200kg/day |

Storage and Warehouse

| Freezer | 416㎡(capacity: approx. 330 tons) |

| Refrigerator | 214㎡(capacity: approx. 122 tons) |

| Grinding factory refrigerator | Capacity: Approximately 210 tons |

Food Safety Policy

- We aim to maintain and improve customer satisfaction by establishing a food safety management system that satisfies both our customers and our company.

- We will continue to development and improvement to provide products and services that satisfy our customers.

- Laws and regulations related to business activities: We will comply with the rules and prevent the occurrence of food safety hazards.

- We value communication with our customers, take customer opinions seriously, and make use of it to develop products and improve quality.

- We will actively engage in human resource development and self-development activities to improve quality and service.

- We will continuously improve the food safety management system and realize the requirements.

- The food safety policy will be reviewed regularly to ensure that it is communicated, understood, disseminated and maintained to all employees.

Revised from May 2016.

- OEM

- Production System & Facilities

- Achievement

-

Domestic Award Record

Overseas Transactions - Company Profile

-

Message from President and CEO

Company Profile

Access Details and Map